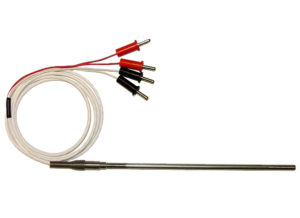

General Purpose RTD Probes

- High linearity and stability for greatest long-term accuracy

- Wide array of configurations and materials

- Custom designs to meet your most demanding requirements

Vulcan Electric Resistance Temperature Detectors (RTDs) are recognized throughout industry for high durability, linearity, and long-term stability. Our RTD element technologies are continually improving, enhancing the quality of the temperature measurements. Vulcan’s designs provide the highest resolution, repeatability and challenging temperature measurement accuracies.

Our custom design capabilities provide you with exceptional process and system engineering flexibility. We are always ready to develop a specific RTD sensor assembly for your most demanding process measurement requirements. We manufacture our rugged probe assemblies in a variety of materials rigid and bendable sheaths, diameters and installation configurations.

- Temperature range -328 °F (-200 °C) thru +1562 °F (+850 °C)

- Standard temperature rated for use up to 1112 °F (600 °C)

- Rigid and bendable sheaths

- Teflon® coated probes available

- Elements 100 or 1000 ohm, Class A (0.06%) or B (0.12%)

- Curve European 100 ohms @ 0 °C= 0.00385 ohms/ohm/degree C

- Curve American 100 ohms @ 0 °C =0.00392 ohms/ohm/degree C

- Thin-film or wire-wound, Platinum, Nickel or Copper

- Sheath Diameter: 3mm (1/8″), 4.5mm (3/16″), 6.3mm (1/4″)

- Sheath length: there is no upper limit on sheath length. The minimum practical length is 2 inches.

- Lead configurations: 2, 3 & 4-wire, single + dual element

- Quick disconnects standard & custom

- Enclosures: standard and explosion proof

- Transmitters: Isolated 4-20 mA, DIN rail and head mount, standard & explosion proof.

- Thermowells

- Automotive, engine test cells

- Co-Energy, solar, coal-gasification, fossil fuel, & nuclear

- Fuel cells

- Food & Beverage

- Ovens & Chillers

- Industrial processes

- Medical

- Pharmaceuticals

- Chemical & Petrochemical

- R&D