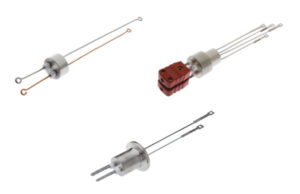

Thermocouple Vacuum Feedthroughs

- Ceramic to metal constructions

- Thermocouple Feedthrough Types T, K, J, R/S, C, or E

- Internal Pressures from 1×10-10 Torr up to 3500 psig

- Temperature Range of -269° C to 450° C (-452° F to +840° F)(Extreme ratings are with plug disconnected and vary depending on the part number)

- Number of Pairs: 1, 2, 3, 5 or 10

The Vulcan Electric Ceramic to Metal Thermocouple Feedthroughs are manufactured with premium grade thermocouple alloys or compensating materials (depending on calibration type). The utilization of specific thermocouple alloys for the feedthrough construction ensures optimum accuracy without introducing measurement error due to incompatible feedthrough materials . The precise measurement of electromotive force (EMF) generated at the thermocouple sensing junction is transmitted through the entire length of interconnecting thermocouple grade alloys or compensating materials directly to the instrumentation. In addition to the matching alloy construction, each feedthrough is engineered and manufactured to ensure hermetic integrity and electrical isolation over an extensive range of operating conditions and temperatures including cryogenic temperatures. Exceptional performance and longevity is achieved by incorporating premium grade materials such as high purity and high strength insulation materials, conductor materials, contacts, and hardware metals.

- ISO KF flanges

- ConFlat® flanges

- NPT (National Pipe Thread) fittings

- Custom plates, flanges, and other options

- Vacuum Furnaces and Ovens

- Geothermal energy exploration

- Semiconductor processing equipment

- LED processing equipment

- Solar processing equipment

- Energy research

- Aerospace

- In-vacuum coating

- Power generation measurement and control

- Industrial equipment and Processes