General Purpose Thermocouples

- Heavy-duty thermocouples for industrial applications

- Rugged and reliable under harshest conditions

- Premium materials, configured to meet your needs

Vulcan Electric designs and produces a wide assortment of thermocouple constructions for industrial applications. Many of these products are custom designed for a specific process requirement. We begin with our decades of engineering experience to ensure complete thermocouple design compatibility. Then we select premium materials and components for durability and maximum longevity. These heavy-duty thermocouples are designed for use in severe and complex process applications where performance reliability is critical. We have the capability to design and manufacture numerous calibration types, configurations, and material combinations.

Every Vulcan thermocouple is constructed of premium materials and components for durability and maximum longevity. Each one is manufactured and tested to precise specifications to make certain they perform to your exact temperature sensing and controller requirements.

- ANSI Type Calibrations: K, J, T, E, N, S, R, B, PII, C

- Protection Tubes: Alumina & Mullite Ceramics, Silicon Carbide and Single-Phase Silicon Carbide, Metal Ceramic tubes, Refractory Laminated, Mild Steel, 304SS, 316SS, 446SS, Inconel 600 & 601, Cast Iron.

- Back-filled and Sealed assemblies for type C calibration

- Process fittings and Flanges

- Thermowells

- Enclosures for General and Explosion proof

- Hot junctions: Grounded, Ungrounded & Exposed

- Transmitters 4-20 Ma

- Metal Heat Treating, Vacuum, Molten Salts, Atmosphere Furnaces

- Gun Manufacturing

- Nuclear

- Steel Foundries

- Aluminum Foundries

- Ceramic Kilns

- Co-Energy

- Chemical & Petrochemical Plants

- Glass, Fiberglass

- Plastics & composites

Models and Options

Plastics Industry Thermocouples

Plastics extruder melt type stainless steel thermocouple assemblies allow maximum service temperatures of 900-F.

Sensor LockTM

Long Life Thermocouple Temperature Sensors

Vulcan Electric’s new thermocouple and RTD is designed for long life under the toughest of conditions.

Introducing a new patented line of thermocouple (RTD) temperature sensors for use in industrial and commercial applications where temperature measurement and control is utilized.

Vulcan Electric’s new “SENSOR-LOCK” sensors give maximum life to the sensing element where others fail. We employ a unique patented positive locking device to accomplish the goal of securing the sensor’s outer flexible jacket inside the adaptor into which the unit is placed. In so doing, the device prevents the jacket from rotating while inside the adaptor.

The rotation of the outer flexible jacket is often responsible for premature sensor failure. Vibration from hydraulic motors or jarring action of any kind causes the stainless steel jacket of the sensor to twist. Since the rigid wire sensing element inside the jacket has been fixed at its connection end, it resists movement. At the sensing tip of the sensor, the rigid wire element is fixed to the jacket. It is here that the fragile element is twisted the greatest amount, due to jacket rotation, and eventually breaks.

Vulcan Electric’s new patented locking device prevents this twisting motion and relieves mechanical stress, resulting in greatly reduced maintenance costs caused by frequent thermocouple or RTD replacement as well as the minimization of lost production due to downtime.

Our positive locking device, by stopping sensor rotation, prevents any possibility of the sensing tip losing contact with the surface being monitored, assuring consistent, accurate temperature sensing.

The patented design of these outstanding sensors includes a sensing tip consisting of a fraction of the mass of a traditional thermocouple tip providing rapid response to temperature changes ultimately providing closer control of temperature and improved product quality.

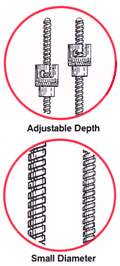

Additionally, “SENSOR-LOCK’s” narrower than normal jacket diameter enables these new sensors to be retrofit into standard adaptors and machine Wells without reboring or retapping.

The “SENSOR-LOCK” sensors install in exactly the same manner as conventional bayonet style cap sensors. The difference is… our positive locking mechanism engages automatically during installation, securing the outer jacket and preventing damaging rotation that often occurs during normal operation. No tools necessary!

Vulcan Electric has elevated temperature sensing technology to meet today’s manufacturing needs for quality and economy. We have taken the adjustable depth concept one step further. Our positive locking mechanism virtually eliminates the problems traditionally associated with adjustable depth sensors by offering the security of a fixed length bayonet style sensor while providing all the advantages of adjustable depth technology.

The “SENSOR-LOCK” sensor can be precisely adjusted to the working depth of any fixed length standard size sensor and eliminates the inventory nightmare of keeping track of dozens of part numbers. ONE “SENSOR-LOCK” sensor will fit any machine in the industry that uses standard diameter sensors.

Sensor LockTM Features

“SENSOR-LOCK” sensors install in exactly the same manner as conventional bayonet style cap sensors. The difference is… our patented positive locking mechanism engages automatically during installation to secure the outer jacket from damaging rotation. The lock is secure and automatic… NO TOOLS NECESSARY!

“SENSOR-LOCK” sensors can be precisely adjusted to the working depth of any fixed length standard size sensor. One “SENSOR-LOCK” sensor will fit any machine in the industry that uses standard diameter sensors.

The “SENSOR-LOCK” thermocouple’s patented design includes a sensing tip consisting of a fraction of the mass of a traditional thermocouple tip, assuring rapid response to temperature changes and ultimately providing closer control of temperature and higher quality control.

“SENSOR-LOCK’s” narrower than normal jacket diameter, (.235″ instead of the conventional .280″) enables easy retrofit into standard adaptors and machine wells without re-boring or re-tapping.

We also offer:

|

|

|

|

|

|

|

|

|

|

|

|

|