Semiconductor Thermocouples

- High-precision thermocouples for high-tech industries

- New, Refurb, Recycle and Reclaim options for flexibility

- Quality Assurance Program meets highest standards

Vulcan Electric Profile Thermocouples are high-precision temperature sensor constructions designed and manufactured primarily for the Semiconductor, Solar and LED industries. These thermocouples were engineered to address the critical process temperature measurement and control required for those industries. Special precautions are taken against contaminants and to ensure complete materials compatibility. We are a comprehensive source for new Semiconductor thermocouples of numerous shapes, sizes, calibrations and materials. Our specialized services are utilized by many premier manufacturers. We supply profile and spike thermocouples for furnaces, such as:

- Tel

- Kokusai

- ASM

- Aviza/SVG/Thermco

- Axcelis

- BTI/Tempress

- Centrotherm

- MRL

- SVCS

- Tystar

- GT Solar

Our long history of application engineering experience combined with our ISO 9001:2000 certified advanced production and calibration technologies ensure that our products will provide optimum longevity in your equipment and the most accurate temperature sensing available.

- NEW PURCHASE: Our new Profile Thermocouples and manufactured and calibrated to original equipment specification. Our attention to detail in our entire process ensures you product that will perform to your exact critical requirements.

- REFURBISHED: Our Refurbish program offers the greatest cost savings from your damaged and used profile thermocouples. Profile thermocouple life cycles depend on the time and temperatures. During normal cycle times where deterioration due to excessive grain growth or breakage occurs, assemblies can still be rebuilt to like-new condition. After comprehensive evaluation in conjunction with recalibration, a quote is generated. Depending on the actual refurbish cost, the customer may decide to continue with repair or use the precious metal credit towards a new assembly.

- TRADE-IN: Replace On Demand program allows trade-in of used thermocouples for new ones without having to worry about scrap credits. Eliminates the variable of repair cost of R&R and inhomogeneity due to the recycled wire. Less accounting paper work and reduced lead times.

- SCRAP: Reclaim Service customers have the convenience of instant credit with no refining charges for their precious metal. This provides one-stop service, which offsets the price of new profile or spike thermocouple purchase while eliminating disposal cost. Old, no longer in service, assemblies are reclaimed for the precious metal content and a credit or payment is offered.

QUALITY ASSURANCE

Vulcan’s Quality Assurance program ensures that your profile thermocouple is thoroughly inspected and tested during every step of refurbish, calibration or exchange.

- Junctions and connectors are electronically verified for conductivity, integrity and adherence to the wiring.

- Wire is specially annealed which eliminates calibration errors caused by stress or strain, physically tests it at high temperature and reveals any inhomogeneity or contamination.

- Length, Diameter and style of each ceramic is examined and documented.

- The precise location of each measuring junction is verified.

- Replace quartz sheath, ceramics and hardware.

- Every test necessary is conducted to assure the thermocouple meets original specifications and will give repeatable accurate results when placed back in service.

- Each profile thermocouple is supplied with a calibration report traceable to NIST and conforming to the latest national and international specifications and criteria

- Horizontal Diffusion Furnaces

- Vertical Diffusion Furnaces

- Custom Process Furnaces

- Rapid Thermal Processing

- Silicon Crystal Growing & Fabrication

- Sapphire Crystal Growing & Fabrication

- Research and Development

- Vacuum Furnace Technologies

- Chemical Vapor Deposition

- Annealing Furnaces

- Silicon Oxidation Processes

- EPI Furnace Processes

- Susceptors

- Ultra Pure Steam

- Semiconductor Compounds

- Other Specialized Applications

Profile Furnace Thermocouples

Vertical Oxidation Furnace Profile Thermocouple

Vertical Furnaces Four & Five Junction Profile Thermocouple

300mm Vertical Profile Furnaces

SVG Auto Vertical Furnace Profile Thermocouple

Paddle Boat Profile Furnace Thermocouple

Retractable Reference Profile Furnace Thermocouple

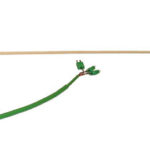

Multi-Junction Staked Plug Profile Furnace Thermocouple

Horizontal Furnace High Temperature Profile Thermocouple

European Horizontal Furnace Profile Thermocouple Duty

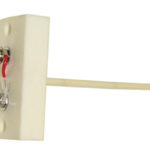

Heavy Duty Handle Profile Furnace Thermocouple

Control Spike Thermocouples

Control Spike Single Thermocouple

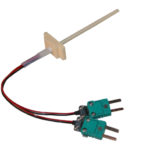

Dual Control Spike Thermocouple

Vertical Furnace Control Spike Thermocouple

Vertical Furnace Over Temperature Thermocouple

Vertical Furnace Control Thermocouples

Vertical Furnace Control Thermocouples

300mm Vertical Control Spike Thermocouple

200mm Vertical Control Spike Thermocouple

Semi Tools Sensors

KF Flanged Vacuum Chamber Thermocouple

Flexible Thermocouple for High Temperature Vacuum

AMAT ASP Chuck Thermocouple

Susceptor Thermocouple

Vertical Furnace Torch Dual Thermocouple

Rapid Thermal Processor High Temperature Thermocouple

Rapid Thermal Processor Single Wafer Furnace

Ultra High Temperature Bayonet Style Thermocouples

Bayonet Style Dual Control Thermocouples

Rapid Thermal Processors Dual Control Spike Thermocouple

Transition Style for Vacuum Feed Throughs

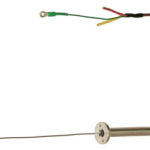

Epitaxial Reactors Metal Sheath Profile Thermocouple